%20copy.png?width=1629&height=840&name=SAFETY%20(500%20x%20300%20px)%20copy.png)

It is important that the Health & Safety Program is developed on a consultative basis between management and workers to ensure the effective implementation of all policies. We encourage all workers to participate by providing feedback during a safety meeting, safety talk, or addressing the health & safety department.

ESS educates all new employees about the organization’s safety

culture, policies, procedures, as well as provide a clear understanding of expectations and requirements as an employee.

Our policy & procedures initiate our course of action for the development of our Health and Safety Management System which forms the basis of our safety program. The policies and procedures support our ongoing commitment to workplace safety and the health of our employees & customers.

Fire safety is one of the most basic types of safety training, and yet it is often overlooked. This is serious because fires can be a common occurrence at construction sites. The combination of combustible substances, open flame (from torches, for example), and poor ventilation in some construction areas create extremely hazardous conditions with a high risk of fire.

✔ Familiarize yourself with the location of all fire exits, alarms and fire extinguishers.

✔ Keep fire exits clear at all times.

✔ Make sure enough fire extinguishers are in the area. Replace empty fire extinguishers immediately.

✔ A fire extinguisher inspection must be carried out at least once per month and date tags must be visible on the extinguisher.

✔ Know how to use the fire extinguisher properly and know which type of extinguisher to use on which class of fire. Using the wrong type of extinguisher can cause the fire to spread.

✔ Always store flammable materials in proper containers, away from buildings and ignition sources.

✔ Post warning signs identifying the areas where flammable liquids are being used.

✔ Wear clothing that are flame-resistant. If the job allows you to wear personal clothing, make sure it is made from organic material. Synthetic materials will catch fire easily and cause burns.

✔ Beware of sparks from tools and other sources.

✔ Know the classes of fire. A Class A fire involves natural combustibles such as wood; Class B fires involve flammable liquids such as bitumen or gasoline, and Class C fires involve electrical fires and combustible metals such as magnesium.

These minimum training and equipment requirements, if followed correctly, will greatly reduce the risk of serious injury on the job site. For more information regarding this subject, please reference the applicable sections of the Occupational Health & Safety Regulation.

SiteDocs Safety Corp. exists to provide resources to the construction industry, and as such, can not be held responsible in any way for the hazardous attitudes, actions or behaviors of any worker, or for unsafe working conditions. Furthermore, SiteDocs Safety Corp. assumes no responsibility for any misinformation contained in these resources as they do not supersede provincial or Federal Regulations. Therefore, it is the user's sole responsibility to become acquainted with the requirements as set forth in the Worker's Compensation Act and the Occupational Health & Safety Regulation as it relates to their respective industry.

Lockout/Tagout is more than just putting a red lock on the main electrical disconnect to a machine or part of a machine. There are 7 very important steps you must do when putting Lockout/Tagout in place:

NOTIFY – Notify all affected employees that you are going to be conducting a lockout/Tagout.

PREPARE – Before you begin, be sure you know all the types of energy involved, hazards presented by energy, and how to control the energy.

SHUTDOWN – Turn off the machine or equipment.

ISOLATE - Isolate machine or equipment from its energy source(s). (For example, turn off the main circuit breaker.)

LOCKOUT – apply your lock. Be sure that it holds the isolating device in the “off” or “safe” position.

RELEASE - Release stored energy. Relieve, disconnect, restrain, block, or otherwise ensure, that all energy sources – electrical, mechanical, hydraulic, compressed, etc. – are de-energized.

VERIFY – Try the on-off switch or other controls to be sure the machine won’t start. Return the switch to the “off” position.

Your Lockout is Complete!

In Canada over 42,000 workers get injured annually due to fall incidents. This number represents about 18% of the "time-loss injuries" that were accepted by workers' compensation boards or commissions across Canada (based on statistics from the Association of Workers' Compensation Boards of Canada, 2016).

Statistics show that the majority (67%) of falls happen on the same level resulting from slips and trips. The remaining 30% falls from a height. This document will summarize information on "falls on the same level" (slips and trips). Falls from an elevation, such as falls from ladders, roofs, downstairs or from jumping to a lower level, etc., is discussed in the Safety Belts, Harnesses, and Lanyards document since each type of fall requires different features in a fall prevention program.

Slips happen where there is too little friction or traction between the footwear and the walking surface. Common causes of slips are:

Trips happen when your foot collides (strikes, hits) an object causing you to lose balance and, eventually fall. Common causes of tripping are:

How to prevent falls due to slips and trips?

Both slips and trips result from some kind of unintended or unexpected change in the contact between the feet and the ground or walking surface. This fact shows that good housekeeping, quality of walking surfaces (flooring), selection of proper footwear, and appropriate pace of walking are critical for preventing fall incidents.

Housekeeping

Good housekeeping is the first and the most important (fundamental) level of preventing falls due to slips and trips. It includes:

Without good housekeeping practices, any other preventive measures such as installation of sophisticated flooring, specialty footwear or training on techniques of walking and safe falling will never be fully effective.

For more information about effective housekeeping visit the OSH Answers document on Workplace Housekeeping - Basic Guide.

Flooring

Changing or modifying walking surfaces is the next level of preventing slips and trips. Recoating or replacing floors, installing mats, pressure-sensitive abrasive strips or abrasive-filled paint-on coating, and metal or synthetic decking can further improve safety and reduce the risk of falling. However, it is critical to remember that high-tech flooring requires good housekeeping as much as any other flooring. In addition, resilient, non-slippery flooring prevents or reduces foot fatigue and contributes to slip prevention measures.

Footwear

In workplaces where floors may be oily or wet or where workers spend considerable time outdoors, prevention of fall incidents should focus on selecting proper footwear. Since there is no footwear with anti-slip properties for every condition, consultation with manufacturers is highly recommended.

Properly fitting footwear increases comfort and prevents fatigue which, in turn, improves safety for the employee. For more information on footwear visit, the OSH Answers document on Safety Footwear.

What can you do to avoid falling at work? - You can reduce the risk of slipping on wet flooring by:

You can reduce the risk of tripping by:

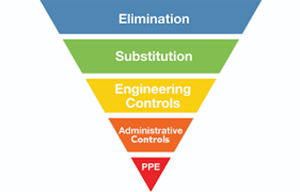

For heat and cold stress policies, when considering the types of controls that can be put in place, we will go by the established Hierarchy of Controls:

*Elimination

*Substitution

*Engineering

*Administrative

*PPE

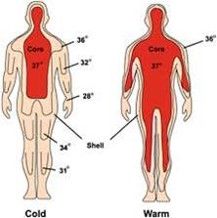

While heat may be a concern during the summer months, many problems occur when workers are just getting used to the temperature extremes. Most people feel comfortable when the air temperature in a room is between 18°C and 22°C and when relative humidity ranges from 30-50%.

*The heart rate increases to move blood -- and heat -- from the heart, lungs, and other vital organs to the skin.

"Sweating increases to help cool blood and body. Sweating is the most important way the body gets rid of excess heat.

When there isn’t enough water for the body to cool itself, dehydration happens which results in other heat-related disorders.

*Environmental conditions: air temperature, humidity, wind speed, and radiant heat (sun).

*Intensity of work/workload.

*Duration of exposure.

*Frequency of work.

*Human factors such as physical fitness, age, medications.

*Type of clothing.

*Pre-existing medical conditions – check with a medical care provider to ensure that it is suitable to work in heat

|

Factors to consider in the Heat |

|

|

Weight |

Overweight can cause being less efficient at losing heat |

|

Poor Physical Condition |

Your physical condition decreases your ability to cope with the heat |

|

Previous Heat Illnesses |

Sensitivity to heat if the previous heat-related illness has occurred |

|

Age |

As the body ages, sweat glands become less efficient |

Factors to consider in the Heat |

|

|

Heart Disease or High Blood Pressure |

Heart rate increases in order to pump blood to the skin to cool the body |

|

Recent Illnesses |

Recent illnesses increase the risk of dehydration & heat stress |

|

Alcohol Consumption |

Consumption in the previous 24 hrs leads to dehydration & increased heat stress |

|

Medication |

Certain drugs may cause heat intolerance |

A summary of heat-stress-related disorders, causes, symptoms, treatment and prevention is presented in the table below. Courtesy of MOL Ontario

|

Cause |

Symptoms |

Treatment |

Prevention |

|

|

Heat rash |

Hot humid environment; plugged sweat glands. |

Red bumpy rash with severe itching. |

Change into dry clothes and avoid hot environments. Rinse skin with cool water. |

Wash regularly to keep skin clean and dry. |

|

Cause |

Symptoms |

Treatment |

Prevention |

|

|

Heat cramps |

Heavy sweating from strenuous physical activity drains a person’s body of fluid and salt, which cannot be replaced just by drinking water. Heat cramps occur from salt imbalance resulting from failure to replace salt lost from heavy sweating. |

Painful cramps occur commonly in the most worked muscles (arms, legs or stomach); this can happen suddenly at work or later at home. |

Move to a cool area; loosen clothing, gently massage and stretch affected muscles and drink cool salted water (1½ to 2½ mL salt in 1 litre of water) or balanced commercial fluid electrolyte replacement beverage. If the cramps are severe or don’t go away after salt and fluid replacement, seek medical aid. Salt tablets are not recommended. |

Reduce activity levels and⁄or heat exposure. Drink fluids regularly. Workers should check on each other to help spot the symptoms that often precede heat stroke.

|

|

Cause |

Symptoms |

Treatment |

Prevention |

|

|

Fainting |

Fluid loss, inadequate water intake and standing still, resulting in decreased blood flow to brain. Usually occurs in unacclimatized persons. |

Sudden fainting after at least two hours of work; cool moist skin; weak pulse. |

GET MEDICAL ATTENTION. Assess need for cardiopulmonary resuscitation (CPR). Move to a cool area; loosen clothing; have the person lie down; and if the person is conscious, offer sips of cool water. Fainting may also be due to other illnesses. |

Reduce activity levels and⁄or heat exposure. Drink fluids regularly. Move around and avoid standing in one place for too long. Workers should check on each other to help spot the symptoms that often precede heat stroke. |

|

Cause |

Symptoms |

Treatment |

Prevention |

|

|

Heat exhaustion |

Fluid loss and inadequate salt and water intake cause a person's body's cooling system to start to break down. |

Heavy sweating; cool moist skin; body temperature over 38°C; weak pulse; normal or low blood pressure; the person is tired and weak, and has nausea and vomiting; is very thirsty; or is panting or breathing rapidly; vision may be blurred. |

GET MEDICAL ATTENTION. This condition can lead to heatstroke, which can cause death quickly. Move the person to a cool shaded area; loosen or remove excess clothing; provide cool water to drink; fan and spray with cool water. Do not leave the affected person alone. |

Reduce activity levels and⁄or heat exposure. Drink fluids regularly. Workers should check on each other to help spot the symptoms that often precede heatstroke. |

|

Cause |

Symptoms |

Treatment |

Prevention |

|

|

Heat stroke |

There are two types of heat stroke: ·Classic heat stroke may occur in older adults and in persons with chronic illnesses exposed to excessive heat. When the body has used up its water and salt reserves, it stops sweating causing a rise in body temperature. ·Exertional heat stroke generally occurs in young persons, who engage in strenuous physical activity for a prolonged period of time in a hot environment and the body’s cooling mechanism cannot get rid of the excessive heat. Heat stroke may develop suddenly or may follow from heat exhaustion. |

High body temperature (over 40°C) and any one of the following: the person is weak, confused, upset or acting strangely; has hot, dry, red skin (classic heat stroke) or profusely sweating (exertional heat stroke); a fast pulse; headache or dizziness. In later stages, a person may pass out and have convulsions. |

CALL AMBULANCE. This condition can kill a person quickly. Remove excess clothing; fan and spray the person with cool water; offer sips of cool water if the person is conscious. |

Reduce activity levels and/or heat exposure. Drink fluids regularly. Workers should check on each other to help spot the symptoms that often precede heat stroke. |

We will not be able to eliminate heat from our worksites, nor will we be able to substitute something for heat. We will therefore rely upon the balance of options to assist us in Heat Stress prevention.

Why wearing a harness is a crucial piece of safety equipment on any job when working at heights! Harnesses require care, maintenance and storage to ensure they function properly every time. Without continuous maintenance, harnesses can officially malfunction and have severe consequences.

Once you have your safety harness, you should ensure it is properly stored by keeping it free of moisture, protected from impact, and away from extreme temperatures. It is recommended that harnesses be stored either hanging, flat, or neatly folded to prevent unnecessary stress or wear.

Harnesses also should be inspected regularly and cleaned as part of a normal equipment maintenance program. The harness can be quickly and easily assessed to ensure if a fall occurs the harness will keep you Safe!

To aid in this process, some harnesses have visual technology built into the straps, providing an obvious color change that indicates a point on the harness may be worn out.

Some harnesses also have impact indicators at key fastening points to show whether the harness has been involved in a fall by displaying a warning that is visible only after impact.

Should a fall protection harness get dirty, the wearer will need to clean it immediately according to the manufacturer’s instructions. If those instructions are not available, most harnesses can be cleaned with a damp sponge and warm, soapy water. After washing with soap, a typical harness should be rinsed thoroughly and hung to dry, preferably not in direct sunlight.

With conscientious storage, regular care, and a little maintenance, a well-made harness will perform at its highest level for many years. Construction workers are tough, but humans are fragile making personal fall protection a top priority when it comes to personal safety. Following these simple steps can be Life-saving and avoid injury!

When workers prepare equipment to be lifted by cranes, hoists or other material-handling machinery – is a common work process on construction sites, shops, among others. Performing rigging operations safely is critical. According to OSHA, rigging workers have been injured or killed when loads have slipped or the rigging has failed.

OSHA notes that riggers must be:

· Properly trained on the hazards associated with rigging jobs

· Qualified and able to comply with all procedures

· Aware of where the crane is operating (surface should be level and firm enough to support the crane and load)

· Familiar with rigging techniques and equipment

· Able to anticipate issues before they happen

· Able to stop a job immediately if unsafe conditions exist

· Aware of the weight of the load and the capacity's of the crane and any rigging gear

When lifting equipment, OSHA offers multiple tips, including:

· Riggers should keep their hands, fingers and feet clear of pinch points.

· Be aware of stacked material when lifting to avoid knocking it over with a swinging load.

· Use a designated spotter during lifting to ensure proper clearances are maintained.

· Check for overhead power lines before lifting a load.

· Warn nearby workers before raising, lowering or swinging a load.

· When setting a load down, check that the landing area is clear and set it down slowly.